Answer

Sep 29, 2025 - 10:22 AM

🔧 If you are pressure testing the line (e.g., hydrostatic pressure test):

-

The valve must be fully installed and properly restrained.

-

The valve must be rated for the test pressure.

-

Most standard gate valves (for water) are rated for at least 200 psi, which is usually sufficient for pressure tests (typically done at 1.5x the working pressure, often around 150–200 psi).

-

-

The valve should be either fully open or fully closed — depending on whether you're testing through it or testing up to it.

-

Be aware that testing against a closed valve puts full pressure on the gate, so it must be seated properly and factory-tested to ensure tight seal.

⚠️ Things to Watch Out For:

-

New valves may have protective coatings or seals that aren't meant to handle high-pressure testing right away.

-

If the valve is on the end of the test section, it must be braced or anchored — gate valves alone are not thrust-resistant.

-

You should not rely on the valve alone as a test plug — use test plugs or temporary end caps for isolated testing when possible.

🧪 Common Water Line Test Setup:

-

Install and restrain the valve.

-

Install temporary thrust blocks or mechanical restraints behind the valve.

-

Use a test plug or cap beyond the valve (preferred).

-

Pressurize the line and monitor per AWWA C600 / C605 testing standards.

-

After the test, disassemble any temporary parts.

💡 Summary:

-

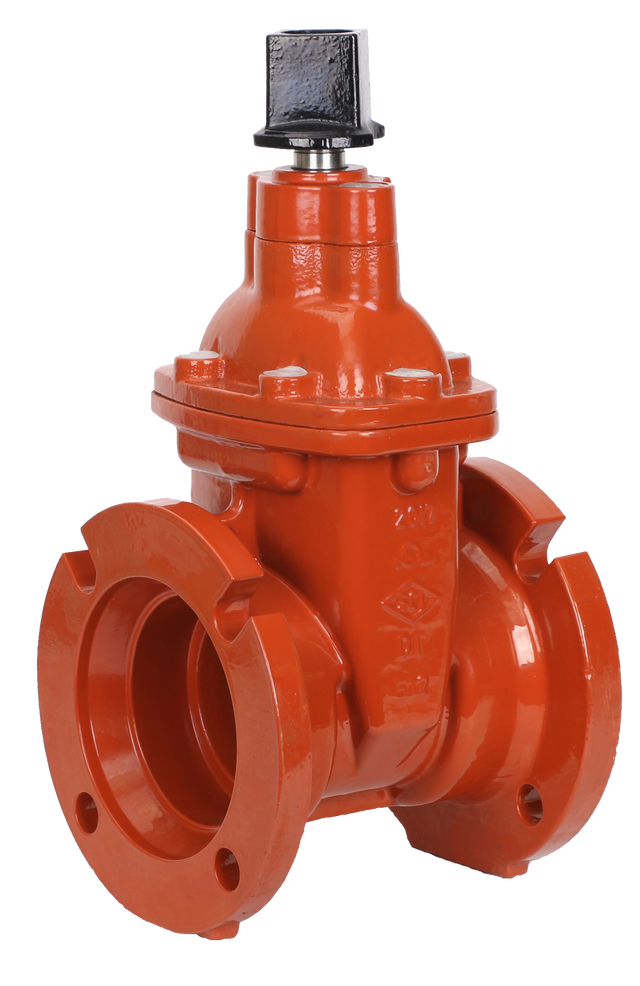

✅ A new 8” gate valve can be used as part of a pressure test on an 8” DIP water line.

-

⚠️ But you should not rely solely on the valve to seal the line during pressure testing without proper restraint and confirmation of pressure rating.

-

➕ Best practice: use a test plug or cap beyond the valve if testing the main line.